Chillers are very widely used in industrial applications and household applications. In industry, chillers play a role in cooling the machine and speeding up the production. In the family, they are used as ice bath machines in hot summer. However, whether in industrial production or in the house, the chiller is inseparable from a topic, that is, how to choose a more energy-efficient chiller to reduce the operating cost?

“Energy efficiency” has been one of the main needs of consumers when buying the products, and it is even more concerned about this point when purchase the high-power industrial chiller. As more and more chiller users pay more attention to “protect the environment, save resources”, Pengqiang manufacturing chiller is also pursuing in the energy-saving to help reduce the chiller running costs, and to promote green industrialized production.

In this article, we will introduce some energy-saving chiller unit starting from the internal parts of the chiller, and help to look for energy-efficient chiller in customer-oriented way.

The root of energy-saving chiller lies in its internal parts. Pengqiang has a variety of customized chiller to choose from. To produce energy-saving chiller, pengqiang will start from the internal parts to optimize. The internal parts which determines whether the chiller is energy-saving are: evaporator, compressor, condenser and expansion valve.

High-efficiency finned evaporator:

The Pengqiang high efficiency finned evaporator, which has also been frequently mentioned in previous articles, is a device based on evaporation principle. The evaporation efficiency is enhanced by an extended surface area and a specially designed fin structure.

The finned evaporator adopts heat exchange technology, which can achieve more efficient cooling effect with less energy consumption, will reduce energy cost. Generally speaking, the material of the finned evaporator are aluminum tube and copper tube. The finned evaporator with aluminum tube is cheaper than the copper tube one. But the quality and effect of the copper tube is better.

Chiller compressor

In order to meet the “energy saving” feature, you can follow the points below when choose a compressor. The compressor is the heart of the chiller, and only the right choice will help to achieve the purpose of energy saving.

compressor has more than one refrigerant circuit

Screw compressor with slide valve

Panasonic scroll compressor

Semi-hermetic compressor

Inverter compressor

Chiller condenser

Condenser is the key to chiller refrigeration. High-quality condenser will also have a more advanced design. During the operation of water-cooled chiller, excellent condenser can optimize the refrigerant and improve the heat dissipation effect, so that the circulating water can be more efficient to complete the heat exchange and achieve energy-saving cooling purposes. For the air-cooled chiller, you can customize the fan parameters, to more efficiently achieve the purpose of cooling.

Expansion valve of chiller

Expansion valve in the chiller plays a role in controlling the refrigerant and water circulation. Excellent expansion valve can accurately control the flow rate to meet the demand in actual operation of the chiller, to avoid too much or too little refrigerant enter into the evaporator. Otherwise, it will increase the unnecessary refrigerant loss and excessive electrical energy consumption.

The reasonable control of refrigerant flow through the expansion valve can also reduce the load of the chiller compressor. This way, the chiller will work in more reasonable flow of resources so as to reduce the energy waste.

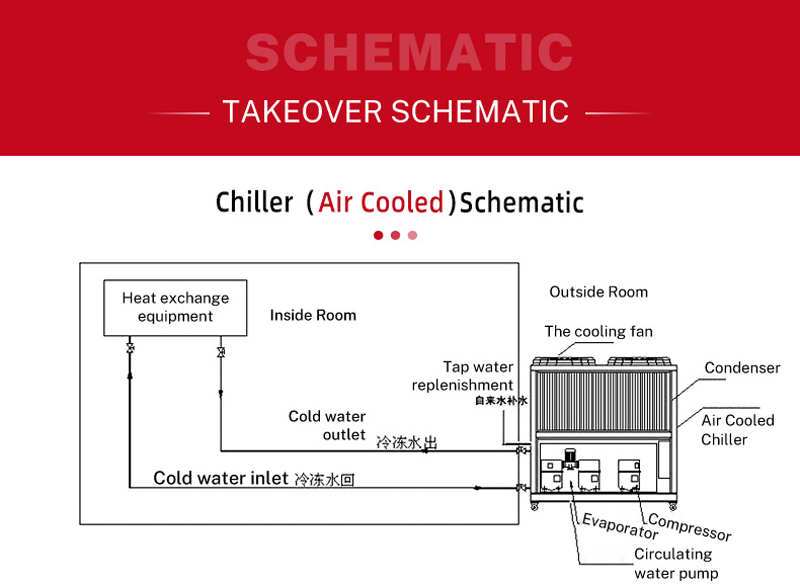

Air-cooled chiller

Air-cooled water chillers do not need external water circulation system during operation, they can cool down the water through the fan. So air-cooled water chillers do not need to use the water pump and water tower. It is not only save money to buy water tower, but also saves the consumption of resources caused by the operation of the pump.

The scope of application of air-cooled chiller is relatively larger than water-cooled chiller. The function of air cooled chiller determines that it can work without requiring a large amount of water. So it can be used in areas where there is a lack of water resource and save the use of water and energy.

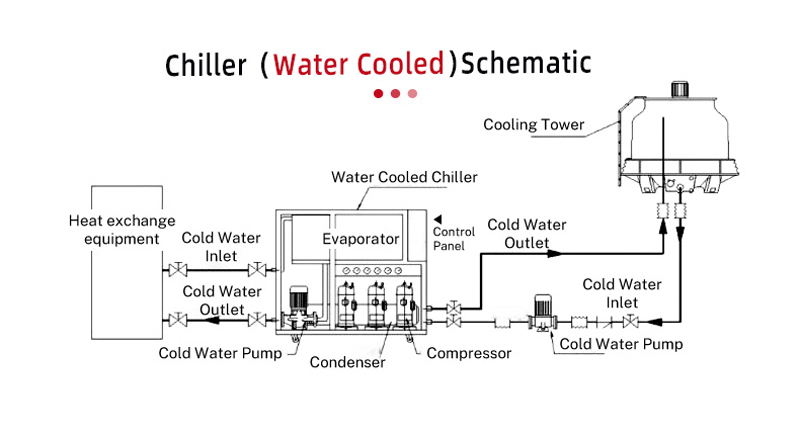

Water-cooled chiller

Water-cooled chiller needs external cooling tower for water circulation cooling. The external cooling tower is more effective in heat dissipation and refrigeration work.

In the large fixed rubber and plastic assembly line, water-cooled chiller is a very good choice. The cooling effect of water cooled chiller will be more stable and efficient in the high heat environment.

The working principle of water-cooled chiller have also been mentioned in Pengqiang previous articles. It is cooling down the temperature mainly through the water cycling. It will require amount of water in the installation of the water storage period. When start running, there will be no waste of water resources.

The second premise of energy saving is from the maintenance of the machine. The chiller is in contact with water all the year round, easy to produce scale. When using the water cooled chiller, customers should also observe whether there are microorganisms in the water tower. If the chiller is not regularly maintained, the chiller is easy to be affected, thereby increasing the energy consumption of the chiller.