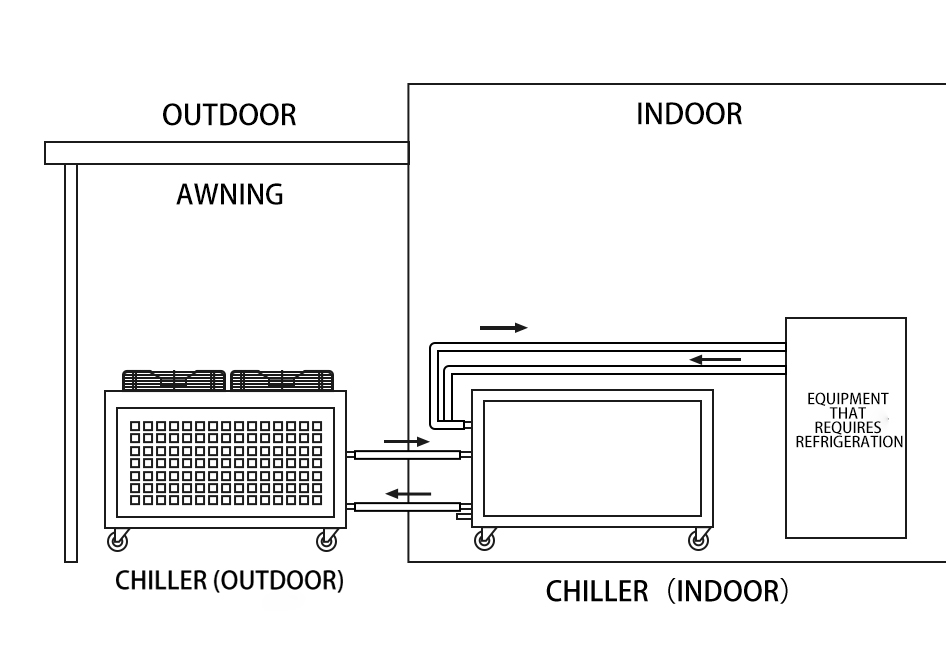

Split chillers are ideal for areas with limited space for installation with high noise levels or low heat dissipation requirements. For instance, in offices, laboratories and other locations that require silence, the split design puts the source of noise outdoors. In rooms that are poorly ventilated, the heat is transferred into the outdoors via pipes to discharge.

Additionally, split chillers can be used for long-distance cooling as well as easy maintenance. They are frequently employed in medical equipment, electronic manufacturing, as well as other fields, providing effective as well as reliable solutions to cooling for production in industrial settings.

Installation that is flexible Flexible installation: Designed as separate units, both the indoor and outdoor units cater to areas with limited space or intricate arrangements, allowing for a more adaptable installation process.

Noise is low: the primary source of noise (such as a compressor) is outdoors, which drastically minimises indoor noise and is ideal for locations where there are high environmental demands.

Effective heat dissipation: Heat is transferred outdoors via pipes, effectively addressing the issue of inadequate ventilation or heat concentration as well as improving the efficiency of heat dissipation.

Simple maintenance Split structure: The split structure is simple to maintain, while the outdoor component can be placed in a separate location without impacting the indoor equipment's operation.

The scope of applications is vast. This includes long-distance refrigeration. It is able to meet the cooling requirements of large equipment or even many areas and offers many different applications.

Frequency: It is recommended that split chillers undergo maintenance every three to six months; however, the frequency of maintenance required is contingent upon the usage environment and load.

Cleaning: When you are cleaning, make sure to turn off the power so that water does not splash into the electrical components. Additionally, make sure to clean the condenser, evaporator, and filter on a regular basis.

Refrigerant Levels: Refrigerant pressure and liquid level should be checked on a regular basis, and if they are found to be insufficient, they should be refilled in a timely manner to prevent any degradation or damage to the system.

Electrical Components: Electrical components should have their wiring tightness, age, and functioning status checked on a regular basis to ensure that they are running in a safe and stable manner.

Space-limited environments: such as small factories or laboratories, the split design allows for flexible placement and saves indoor space.

Noise-sensitive areas: For example, offices, medical equipment rooms and other places with high noise requirements, the outdoor unit reduces indoor noise.

Areas with poor heat dissipation conditions: such as closed or poorly ventilated places, the split design can discharge heat to the outside to ensure efficient operation of the equipment.