5HP chillers are utilized in the production of automotive components to cool precision machinery, ensuring that critical equipment like CNC machine tools and injection molding machines sustain a consistent temperature. The chiller enhances machining precision, eliminates equipment overheating, prolongs equipment lifespan, and minimizes downtime through effective cooling, consequently augmenting production efficiency and product quality.

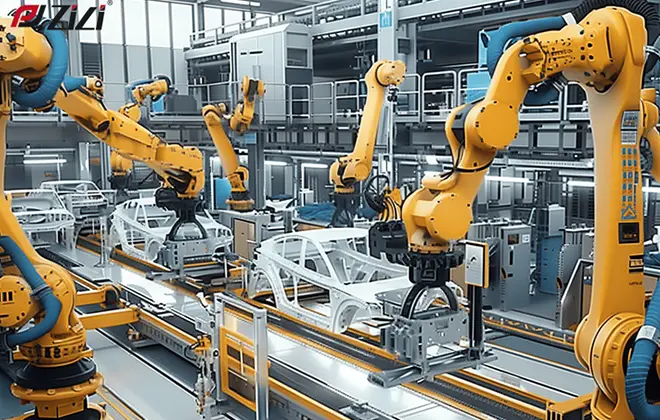

An automotive parts manufacturer focuses on manufacturing high-precision molds and plastic parts, where rapid cooling of plastic parts is crucial. During the processing, the heat generated by machine tools and injection molding equipment will affect product precision and material properties, and efficient cooling is required to keep the equipment running stably.

5HP chillers deliver cooling for injection molding machines, CNC machine tools, and other apparatus via a chilled water circulation system. The chilled water generated by the chiller is conveyed to the cooling section of the processing equipment via pipes to dissipate excess heat, maintain optimal temperatures for the mold and machine tools, and enhance processing precision.

Compact and convenient: The 5HP chiller is diminutive in dimensions and simple to install. It is appropriate for adaptable implementation on the production line to satisfy the cooling requirements of diverse small equipment and is user-friendly.

Enhance production efficiency: Sustain consistent equipment temperature to minimize downtime and failure rates attributed to temperature fluctuations, consequently augmenting production efficiency and assuring the stability and continuity of automotive parts manufacture.