Refrigerant is a very important component of the chiller. Almost all the refrigeration effects of the chiller rely on the refrigerant. If there is a problem with the refrigerant during the operation of the chiller, the production efficiency will be reduced. Then this kind of How should the situation be prevented? How to prevent it? I think this informative article about industrial chiller refrigerants will help you.

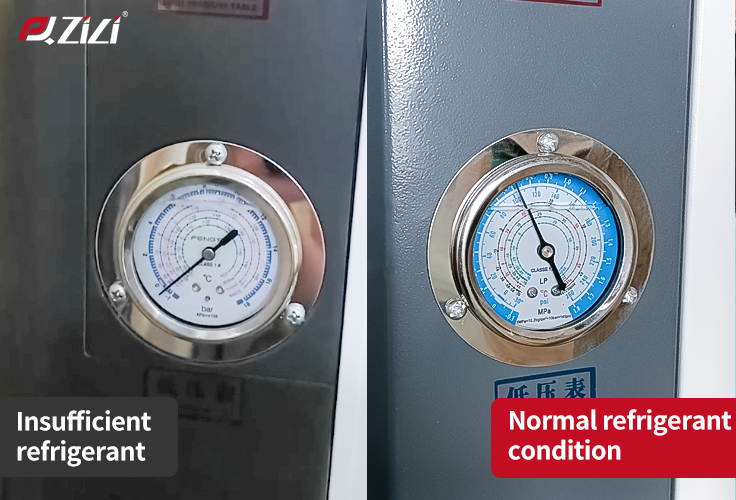

Insufficient refrigerant charge can have a variety of negative effects on industrial chillers, which may depend on the type of refrigerant, chiller design and operating conditions, Here are some possible impacts:

Reduced refrigeration efficiency: Insufficient refrigerant charge will cause the chiller's refrigeration efficiency to decrease. This means the machine takes longer to reach the required temperature, or it cannot reach the same low temperature in the same amount of time.

Increased energy consumption: The energy consumption of industrial chillers may increase as the refrigeration system takes longer to complete the cooling process. This can lead to increased production costs and wasted energy.

Impact on equipment life: Insufficient refrigerant may cause the chiller to operate under unstable conditions, thereby increasing the risk of wear and damage to the machine. This can impact the life of the equipment, leading to the need for more frequent maintenance and repairs.

Impact on product quality: For certain industrial applications, especially production processes that require maintaining strict temperature control, insufficient refrigerant charge may result in reduced product quality. For example, temperature fluctuations can have a negative impact on certain production processes.

Safety risks: The refrigeration system needs to maintain a certain pressure and temperature when operating. Insufficient refrigerant may cause the system pressure to rise abnormally, increasing the safety risks of the equipment. For example, leakage or failure may cause unexpected situations.

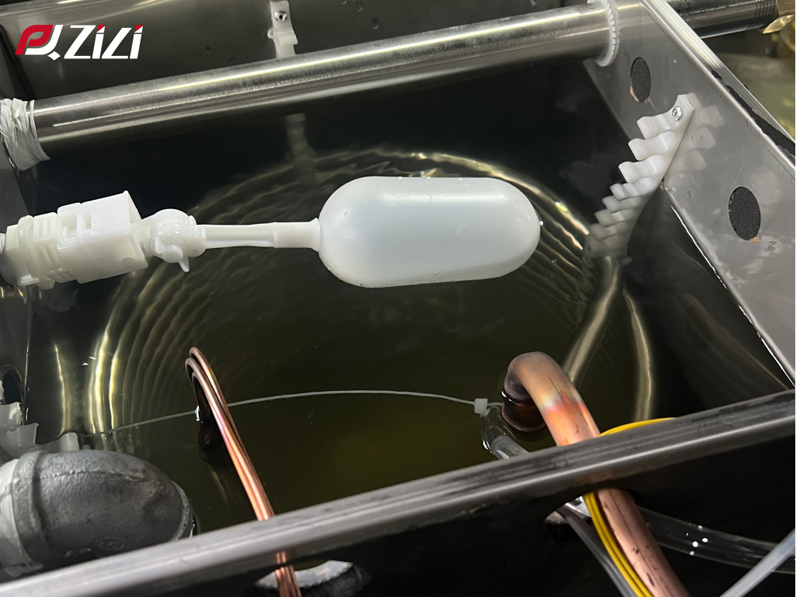

In order to ensure the normal operation of the chiller and increase the life of the equipment, Pengqiang recommends that customers regularly inspect and maintain the chiller, including checking the refrigerant filling amount. If the refrigerant is found to be insufficient, it should be filled by professional technicians.

So in order to prevent the refrigerant charge from being too low, is it okay to charge too much refrigerant into the chiller? The answer is definitely no. Excessive refrigerant charging may cause a series of problems and have a negative impact on the refrigeration system. Here are some typical consequences:

System overpressure: Excessive refrigerant will cause the internal pressure of the refrigeration system to increase beyond the design working pressure. This can lead to damage to system components and pipes, increasing the risk of equipment failure.

Compressor overheating: Excessive refrigerant can cause the compressor to overheat, which may cause the grease to decompose, damage the internal parts of the compressor, and affect its performance and life.

Reduced refrigeration efficiency: Too much refrigerant may cause reduced performance of the refrigeration system. This may manifest as poor cooling, extended cooling times, or the system's inability to maintain a stable temperature.

Increased energy consumption: Excessive refrigerant may cause the system to operate under unstable conditions, thereby increasing energy consumption. Refrigeration systems require more energy to maintain normal operation, resulting in wasted energy.

Oil separation: Excessive refrigerant may cause the separation of oil and refrigerant, reducing the amount of oil in the system. This can lead to insufficient lubrication of the compressor, increasing the risk of mechanical wear and failure.

System failure: Operating at excessively high pressures and temperatures for a long period of time, refrigeration systems may face faster mechanical failure and component failure.

Safety risks: Too much refrigerant may cause system pressure to exceed safe limits, increasing the risk of system explosion or leakage. Some refrigerants may also be harmful to the human body and increase safety risks.

In addition to the amount of refrigerant added, refrigerant leakage is also a problem that is prone to occur during the operation of industrial chillers. However, for the service life of the chiller, timely measures need to be taken to prevent further damage to the system and ensure safety,Here are some possible steps:

Stop using the equipment: Once a refrigerant leak is discovered, stop using the relevant equipment immediately. This helps prevent further damage and mitigate potential safety risks.

Ventilation: If the leaking refrigerant is a toxic gas such as Freon, be sure to maintain good ventilation as much as possible to avoid gas accumulation in enclosed spaces.

Stay away from leak sources: Keep a safe distance as much as possible to avoid direct contact with leaking refrigerant. Some types of refrigerants are harmful to the human body and require appropriate protective measures.

Close valves: Close valves associated with the affected refrigeration system to slow refrigerant leaks.

Contact professional technicians: Refrigerant charging and repair are the tasks of professional technicians. Contact an experienced refrigeration technician or service provider immediately who can evaluate the cause of the refrigerant leak and take appropriate action.

Fix the leak: Once the location of the refrigerant leak is identified, fixing the leak is necessary. This may involve replacing damaged pipes, valves or other components.

System Check and Recharge: After fixing a vulnerability, perform a system check to make sure there are no other issues. The refrigerant is then recharged by professional technicians to ensure that the system reaches the correct operating pressure and temperature.

Recording and prevention: Record detailed information about chiller leaks, including the type, location, repair steps, etc. of leaking refrigerant. Additionally, consider implementing preventive measures, such as regular inspections and maintenance, to reduce the likelihood of future leaks.