Pengqiang explosion-proof chiller is a cooling device specially designed for use in hazardous environments. Its main function is to provide stable cooling effect for industrial equipment, electronic equipment or other systems that require cooling, while ensuring safe operation in potentially explosive environments.

With the rapid development of industrial technology, various industries are developing rapidly, and more and more places need industrial chillers. Therefore, Pengqiang has also started the business of customizing explosion-proof chillers. Explosion-proof chillers can ensure the normal operation of the industrial chain in dangerous working environments. The following is a detailed introduction to industrial explosion-proof chillers.

1.Industrial explosion-proof chillers can ensure safe production

The primary function of industrial explosion-proof chillers is to ensure safe production and protect the safety of workers and production lines.

When ordinary industrial chillers work in flammable and explosive environments, they may cause explosion accidents due to sparks or high temperatures generated by electrical equipment.

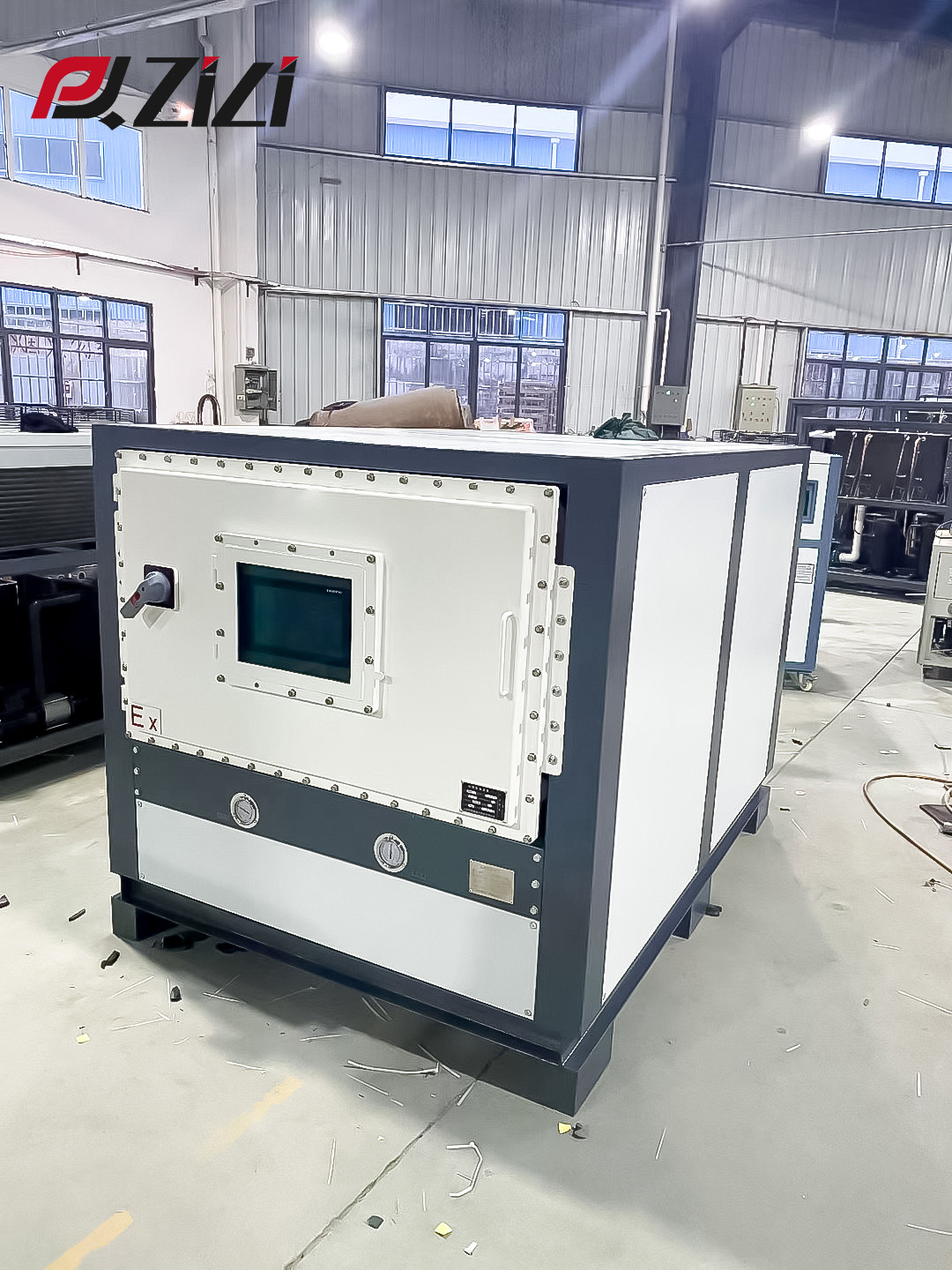

Pengqiang explosion-proof chillers adopt a special explosion-proof design, including explosion-proof electrical components, explosion-proof motors, explosion-proof electric control boxes, etc., which can effectively prevent explosions caused by equipment failure or improper operation and extreme operating environments, thereby ensuring the safety of factories and personnel.

2.Industrial explosion-proof chillers can provide stable cooling effects

Pengqiang explosion-proof chiller can provide continuous and stable cooling effect in dangerous environments.

Its efficient refrigeration system can quickly and stably reduce the temperature of the target equipment or production process, ensuring that the equipment operates within the optimal temperature range and avoiding equipment damage or reduced production efficiency due to overheating. For example, in the chemical and pharmaceutical industries, many processes need to be carried out in a specific low temperature environment, and the stable cooling function of the explosion-proof chiller is particularly important.

3.Explosion-proof chillers can improve production efficiency

By providing a stable cooling effect, explosion-proof chillers can effectively improve production efficiency.

In many industrial production processes, temperature control directly affects product quality and production speed. For detailed chiller usage scenarios, please refer to our previous article. For example, in the plastic processing industry, chillers are used to cool injection molds, which can significantly It shortens the injection molding cycle and improves the molding quality and production efficiency of the product.

Similarly, in the electronics manufacturing industry, explosion-proof chillers are used in extreme environments such as cooling electronic components, which can improve product performance and reliability.

4.Using explosion-proof chillers can extend the service life of equipment

Correct use of explosion-proof chillers can extend the service life of the cooled equipment.

Long-term operation of industrial equipment in a high-temperature environment will accelerate aging and damage, and the cooling function of the explosion-proof chiller can effectively reduce the operating temperature of the equipment, reduce the heat loss of the equipment, and extend its service life.

5.Explosion-proof chillers can meet specific industry needs

Pengqiang explosion-proof chillers are widely used in industries that require strict temperature control and explosion-proof safety. For example, industries such as chemical, petroleum, pharmaceutical, food processing, and military have extremely high requirements for environmental safety and temperature control, and the application of explosion-proof chillers can meet the special needs of these industries.

In these industries, explosion-proof chillers not only need to have powerful cooling capabilities, but also need to be able to operate safely in flammable and explosive environments. The special design and material selection of explosion-proof chillers ensure their reliability and safety under these harsh conditions.

6.Explosion-proof chillers play an important role in energy conservation and environmental protection

Pengqiang's customized explosion-proof chillers also pay more and more attention to energy conservation and environmental protection during the design and manufacturing process.

High-efficiency compressors, advanced refrigerants and optimized cooling system design enable explosion-proof chillers to provide powerful cooling capacity while consuming less energy and having less environmental impact. Many explosion-proof chillers use environmentally friendly refrigerants to reduce damage to the ozone layer, comply with international environmental regulations, and also reflect our company's emphasis on sustainable development.

7.Intelligent Control of Explosion-proof Chiller

Pengqiang explosion-proof chiller is equipped with advanced control system, which can realize intelligent management and operation.

Through the PLC control system and human-machine interface, users can easily monitor and adjust the operating parameters of the chiller, realize remote control and fault diagnosis, and improve the convenience of equipment operation and maintenance efficiency. Pengqiang's intelligent control of the chiller not only improves the operating efficiency of the equipment, but also reduces the risk of human operating errors.

8.Pengqiang chiller customized solution

Many explosion-proof chiller manufacturers are able to provide customized cooling solutions based on the specific needs of customers.

Different industrial applications have different cooling requirements and explosion-proof levels, so Pengqiang's customized explosion-proof chiller industry can better adapt to the specific needs of customers and provide the best cooling effect and safety guarantee.

In summary, explosion-proof chillers play a vital role in industrial production. They can not only provide safe and reliable cooling effects in dangerous environments, improve production efficiency and product quality, but also extend the service life of equipment, meet the needs of specific industries, and pay more and more attention to energy conservation, environmental protection and intelligent control. For those companies working in flammable and explosive environments, choosing a suitable explosion-proof chiller is undoubtedly a wise move to ensure safe production and improve economic benefits.

However, explosion-proof chillers are generally used in flammable and explosive environments, so special attention should be paid to the following aspects to ensure the safe and efficient operation of the equipment and extend its service life, as well as to ensure the safety of workers at work.

1.Installation location selection of explosion-proof chiller

Explosion-proof chillers should be installed in well-ventilated, dry places away from flammable and explosive items. Make sure there is no risk of accumulation of flammable gas or dust around to reduce the risk of explosion.

2.The machine should be inspected regularly

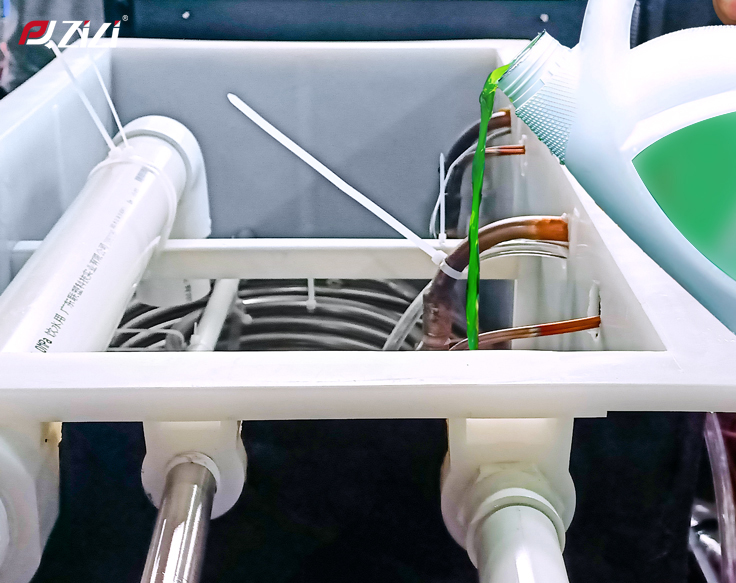

Regularly check the various components of the explosion-proof chiller, including the compressor, motor, condenser and evaporator, to ensure that they are in good working condition. Only when these important accessories are in good condition can the working condition of the explosion-proof chiller be guaranteed. Pay special attention to the inspection of electrical components. The good condition of electrical components is an important guarantee of explosion-proof function. Check frequently to ensure that its explosion-proof performance is not damaged.

3.Cleaning and maintenance

The condenser and evaporator of the explosion-proof chiller need to be cleaned regularly to ensure good heat dissipation. The cleaning of the explosion-proof chiller is no different from that of the ordinary chiller, but you need to be careful not to touch the electrical components with water when cleaning.

4.Refrigerant Management

The refrigerant of the explosion-proof chiller should be checked and replenished regularly. Use refrigerant that meets environmental standards and ensure that there is no leakage during operation. Except for countries that prohibit the entry of refrigerants, our company will prepare refrigerants for use when shipping.

5.Temperature and pressure monitoring

The operating temperature and pressure of the explosion-proof chiller should always be kept within the range allowed by the equipment. Temperature and pressure sensors are installed to monitor the operating status of the equipment in real time. Our company will also install high and low pressure gauges on each chiller to facilitate monitoring and prevent equipment failure or safety hazards caused by excessive temperature or pressure.

6.Explosion-proof component protection

The explosion-proof parts of the explosion-proof chiller should be specially protected to avoid being hit or damaged by external forces. Once the explosion-proof parts are found to be damaged or aging, they should be replaced immediately to ensure that the explosion-proof performance of the equipment is not affected.

7.Protective measures

Warning signs and safety protection measures should be set up in the operating area of the explosion-proof chiller to prevent non-operating personnel from entering. If necessary, fences or protective covers can be set up to ensure the safety of the equipment operating environment.

8.Regular training

Pengqiang recommends that operators be regularly trained to update safety knowledge and operating skills, improve their safety awareness and emergency response capabilities, and ensure that operators are aware of the latest safety standards and equipment operating specifications.