Pengqiang industrial chillers have many types, among which industrial glycol chillers are also one of our products, but this product is a customized product and is usually used for cooling in special industries.

Pengqiang industrial glycol chiller is a device used to cool and maintain the ultra-low temperature required in the production process. This equipment is usually used in industrial applications that require a low temperature environment, such as chemical processes, pharmaceuticals, and food processing, especially chemical processing. The glycol cooler uses ethylene glycol solution as a cooling medium, absorbing and taking away heat through a circulation system to achieve a cooling effect. It is the same as the operating principle of most industrial chillers, but the medium is different.

Refrigeration medium of industrial glycol chiller: The cooling medium of industrial glycol chiller is usually a mixed solution of ethylene glycol and water. Using only pure water as the medium in low temperature will easily cause the water to freeze and damage the chiller itself. Mixing ethylene glycol solution and pure water together can lower the freezing point of water, making it suitable for low temperature work.

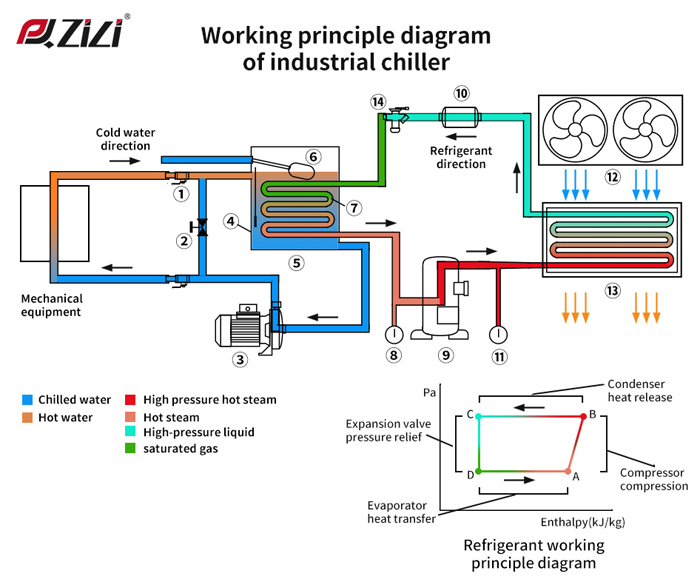

Refrigeration cycle:

Industrial compressor: The refrigerant passes through the compressor in the chiller and is compressed by the compressor, causing the temperature and pressure to rise.

Chiller condenser: The refrigerant that has been treated with high pressure by the compressor enters the condenser, where it is cooled by heat exchange with air or water, releases heat, and is converted into high-pressure liquid.

Chiller expansion valve: The refrigerant processed by the compressor and condenser enters the evaporator through the expansion valve, where the pressure drops suddenly. As a result, part of the refrigerant evaporates and absorbs the surrounding heat, thereby lowering the temperature.

Chiller evaporator: The low-temperature refrigerant evaporates in the evaporator, absorbing the heat of the ethylene glycol aqueous solution and cooling the ethylene glycol solution.

In general, the operating principle of ethylene glycol industrial chillers is similar to that of ordinary chillers. You can refer to our previous articles: What is an industrial water chiller?

Ability to operate at low temperature: Ethylene glycol solution can ensure operation at low temperature, which is suitable for processes with high cooling temperature and environmental requirements.

Ethylene glycol chiller has antifreeze property: Ethylene glycol solution has antifreeze function, avoiding freezing at low temperature and effectively protecting the equipment.

High stability: The glycol chiller designed by Pengqiang can run stably for a long time and is suitable for industrial environments with continuous production.

1.Industrial environments requiring cryogenic cooling

Production needs: When the cooling temperature required by industrial production is lower than the freezing point of water, then the ethylene glycol industrial chiller is an essential auxiliary machine for industrial production. Ethylene glycol aqueous solution can prevent water from freezing at low temperatures, so it is suitable for application scenarios that require low-temperature cooling, such as in pharmaceutical, chemical, and food processing. Most of the processes in these industries require reactions at low temperatures or maintain product stability.

2. Antifreeze protection

Outdoor installation: When an industrial chiller is installed outdoors or exposed to cold environments, if pure water is used as the cooling medium, the low ambient temperature will cause the refrigeration system to freeze and damage the machine itself. The antifreeze properties of glycol chillers make them a safer choice in this case.

3. Stability of temperature control

High-precision temperature control: In applications that require precise temperature control, for example, in very strict production lines such as precision instruments, laboratory equipment, or semiconductor manufacturing, temperature fluctuations may cause unstable equipment performance or deterioration of product quality. The low temperature characteristics of Pengqiang glycol chillers help maintain stable process temperatures and ensure industrial precision production.

4. Special process cooling

Chemical reaction control: Some chemical reactions need to be carried out at low temperatures to control the reaction rate or avoid side reactions. Glycol chillers can provide low enough temperatures to ensure the safety and efficiency of the reaction.

5. High heat load handling

High Load Systems: In specialty industries, there are processes that generate a lot of heat, and in processes that handle large heat loads, glycol chillers can be effective with their efficient cooling performance. They are able to handle the high heat flows in complex processes while maintaining low temperature output.