In modern times, refrigeration equipment has been very popular, whether it is a family or a business, refrigeration equipment play a vital role, of course, in industrial manufacturing, there is no shortage of refrigeration equipment, and our production of industrial chiller, precisely to meet the needs of industrial refrigeration.

Industrial chiller is a specialized cooling system used in various industrial processes to remove excess heat from equipment and machinery during work. It works by circulating chilled water or coolant through a closed-loop system to absorb the heat during the operation of the equipment and then dissipate it into the surrounding environment.

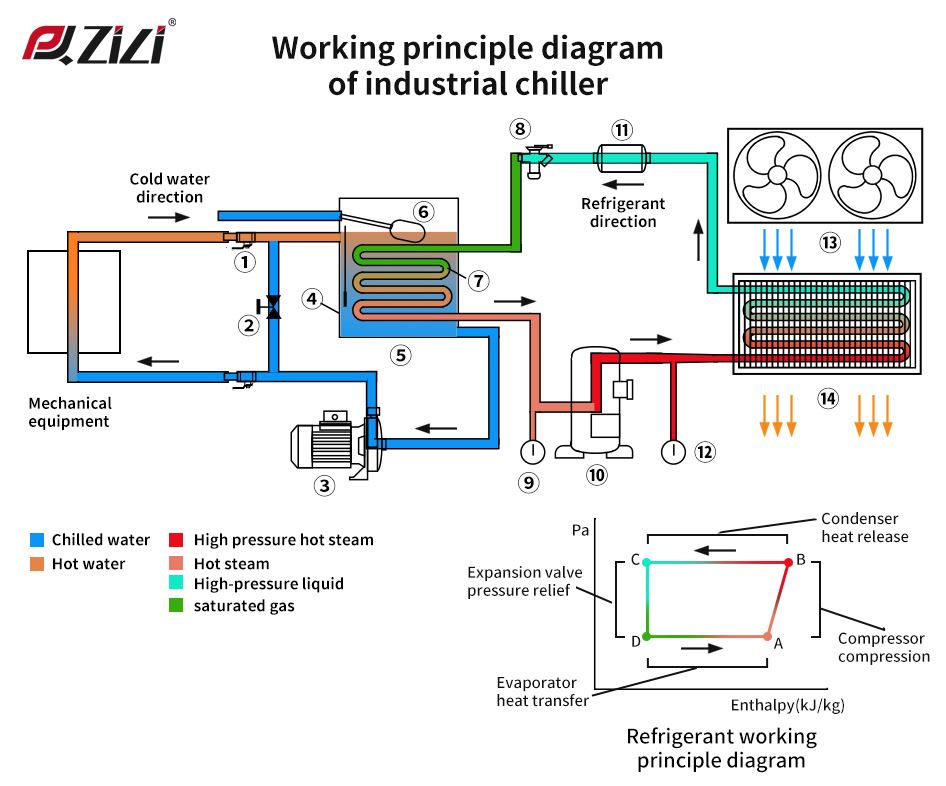

Cooling device: The chiller itself contains components such as compressor, condenser, evaporator and expansion valve. These components work together to facilitate the cooling process.

Circulation pump: The pump circulates chilled water or coolant through a network of pipes to the equipment or process that needs cooling.

Heat absorption: Chilled water is pumped through equipment that needs to remove excess heat. When water absorbs heat, its temperature rises.

Reflux: The heated water returns to the chiller to release the absorbed heat.

Heat dissipation: In a chiller, hot water passes through an evaporator, releasing heat to the refrigerant. This causes the refrigerant to evaporate.

Compression and condensation: The evaporated refrigerant is then compressed by the compressor of the chiller, causing its temperature and pressure to rise. The compressed, high-pressure gas then passes through a condenser, releasing heat and condensing back into a liquid state.

Expansion and cooling: High pressure liquid refrigerant passes through the expansion valve and expands rapidly in the expansion valve. This results in significant cooling of the refrigerant.

Repeat cycle: The cooled refrigerant returns to the evaporator to start the cycle again. The process is continuously cycled to remove heat from the device or process being cooled.

The upper limit of ordinary chiller is not high, which may play a role in small batch production, but in large-scale mass production, the role of ordinary chiller is negligible, and the upper limit of industrial chiller is high and the power is large, which can easily solve these problems.

Ordinary chiller often has only one option of air cooling, because its volume restricts its other mode of operation, while industrial chiller has two options of air cooling and water cooling, which can be chosen according to the customer's own situation.

Compared with ordinary chiller, industrial chiller is more energy saving and cost-effective, can run 24H all year round, save electricity, energy and environmental protection.

Compared with ordinary chiller, industrial chiller has a wider range of applications (interested friends can see our previous article, including the application of chiller in various industries), and even plays a very important role in outdoor plant breeding. If a friend is interested in plant breeding of chiller, we can also write an article to talk about it in detail in the future.

The above is the information about industrial chiller, in addition to the application in the industry, you can also contact our company to customize, applied to the daily ice bath project of small power chiller, our company will provide free customization program, if you like this article and interested in our products, you can leave a message to us, we will contact you in the first time.