Summer is the peak of refrigeration equipment operation, although the industrial chiller is relatively more energy saving and environmental protection, but the use of too high frequency will still cause large power consumption, low efficiency and other problems, to the production side.

Then how to improve the efficiency of the chiller under high intensity use and reduce the consumption of the chiller in high intensity use?

Here are a few things to do:

Maintain the machine to extend the service life of the chiller

Replace with more energy efficient accessories to reduce the cost of continuous operation

Choose merchants with guaranteed quality and price to meet all the needs of the chiller

The refrigerant is the necessary condition for the cold water mechanism, if the refrigerant is not enough to refrigerate, it may lead to the power of the chiller and the power consumption increases, of course, if the refrigerant is added too much, it will also lead to an increase in energy consumption, so the refrigerant content should be moderate.

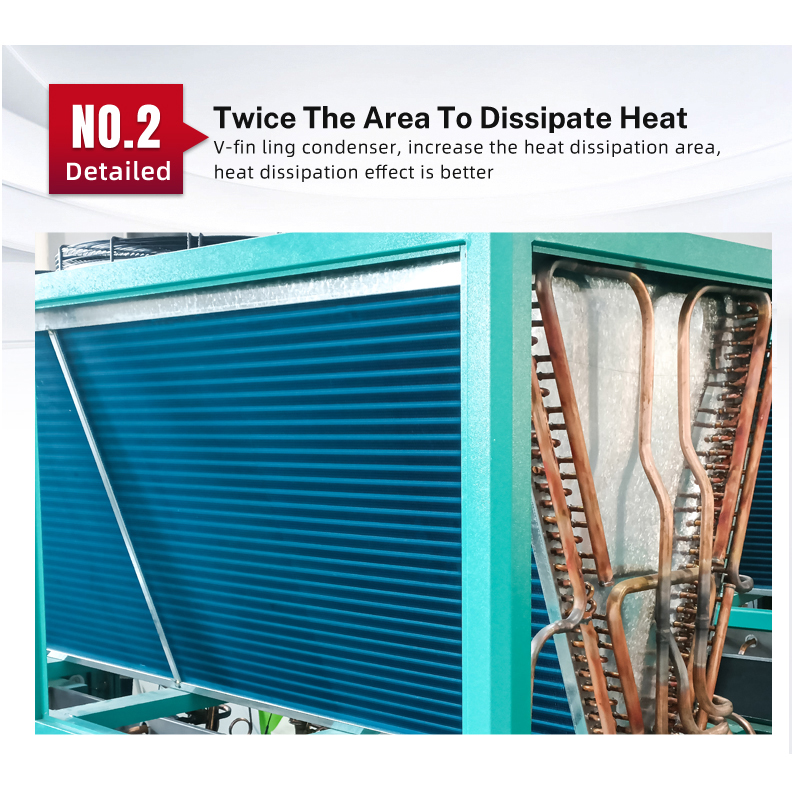

Serious dirt may cause the chiller to require more power to achieve the desired cooling effect, and compared with the slightly dirty chiller condenser, the energy consumption of the seriously dirty condenser is 10% higher than the former, and the clean chiller can save 1-3%, or even reduce the energy consumption of about 9%.

In general, the use of electronic expansion valves will be more efficient than the use of thermal expansion valves, because electronic expansion valves can save about 14% of energy.

Of course, if the load of the chiller is too high, there will also be a situation where the expansion valve cannot control energy consumption.

If the fans are used well, they can also increase the efficiency of the chiller, they can be replaced with EC fans, or an inverter can be added, and the same is true of the water pump, they can be replaced with a new efficient device, or an inverter can be added which will save up to 25% energy.

Our chiller basically adopts frequency conversion function, after the chiller cools to the set temperature, it will stop working, and after the chiller temperature returns, it will continue to start cooling, which can also reduce a lot of unnecessary energy consumption and reduce the customer’s use cost.

Natural cooling means that when the outdoor temperature is below the chilled water set point temperature, heat can be removed from the cooling system with no or minimal use of the compressor, which also reduces energy consumption by approximately 25%.

These are the energy-saving matters required for the high frequency of use of industrial chiller in the summer, and do a good job in the control of energy consumption, which can both improve production efficiency and reduce the cost of use, ensure that the highest production capacity is done at the lowest cost, and better green development.

Our research in the chiller is quite deep, the production of the machine has been praised by many customers, if there is a demand for ultra-energy-saving chiller, our company can also provide customers with free solutions to produce products that make customers satisfied.