In large industrial refrigeration environments (such as hotel space refrigeration, product production lines), multiple chillers are often required for combined cooling to achieve the desired cooling.

A professional industrial chiller system requires a detailed chiller design plan to cooperate with the designed pipelines for large-area, high-power cooling. A chiller combined with multiple chillers can also bring higher cooling efficiency and solve the problem. Many problems arise in production, and it also has more advantages than single or non-combined chillers.

1. Chiller fault tolerance rate

A systematic chiller has a higher fault tolerance rate than a single chiller. If one of the chillers fails during the operation of the chiller, with excellent unit design, the production line will not be paralyzed, and the other chillers will continue to operate as usual. ensure the normal operation of the refrigeration line and reduce production losses.

Once a chiller that does not form a chiller unit fails, it will affect the cooling work of the production line and fail to meet production needs.

2. Energy saving and emission reduction

Green production is a hot topic at the moment. Under certain circumstances, the chiller can be operated systematically through the equipped smart panel, and corresponding adjustments can be made according to the conditions of each unit. Frequency conversion can be performed according to the production situation to reduce the workload of the unit. Energy consumption is reduced to the greatest extent.

However, it is difficult for a single chiller to save energy in a large-scale refrigeration environment, because all cooling objects need to be cooled within a specified time. A single chiller can only mobilize all energy to work, and the machine load is greatly increased. Not only can it not Meeting energy-saving standards will also increase the loss of the chiller itself.

Generally speaking, chillers are generally used in medium and large buildings, such as hotels, apartment complexes and other places where central air conditioning is used. Chillers act as a centralized cooling system to provide cooling for even multiple buildings.

Chiller systems in large buildings use cooled water to circulate through the building to provide cooling for the facility and remove heat from the building.

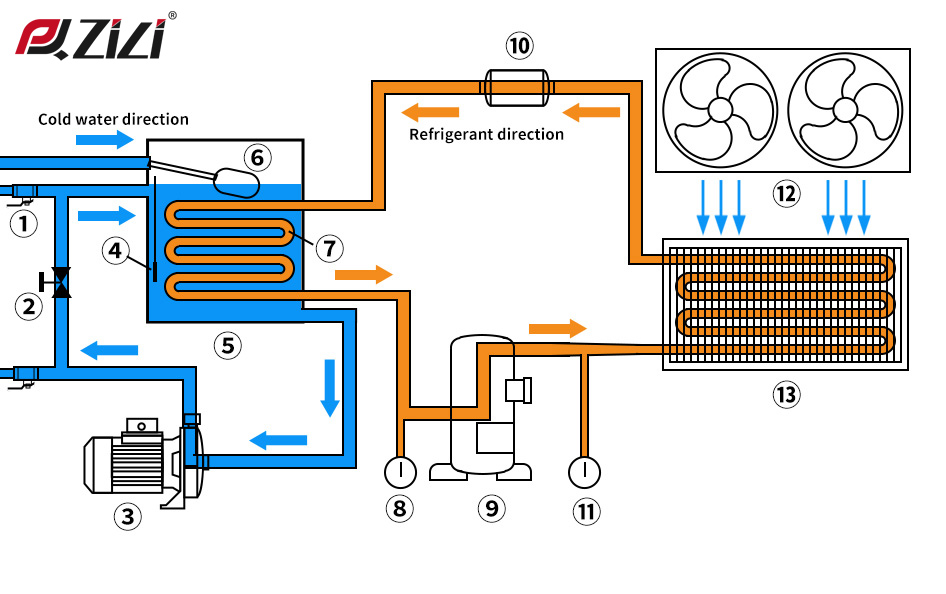

Air-cooled chiller: If it is an air-cooled chiller, after the heat absorbed by the chilled water in the building is circulated back, it will be dissipated directly through the fan, and the heat will be transferred to the outside air. The heat dissipation method is similar to the air conditioner external unit used in our home.

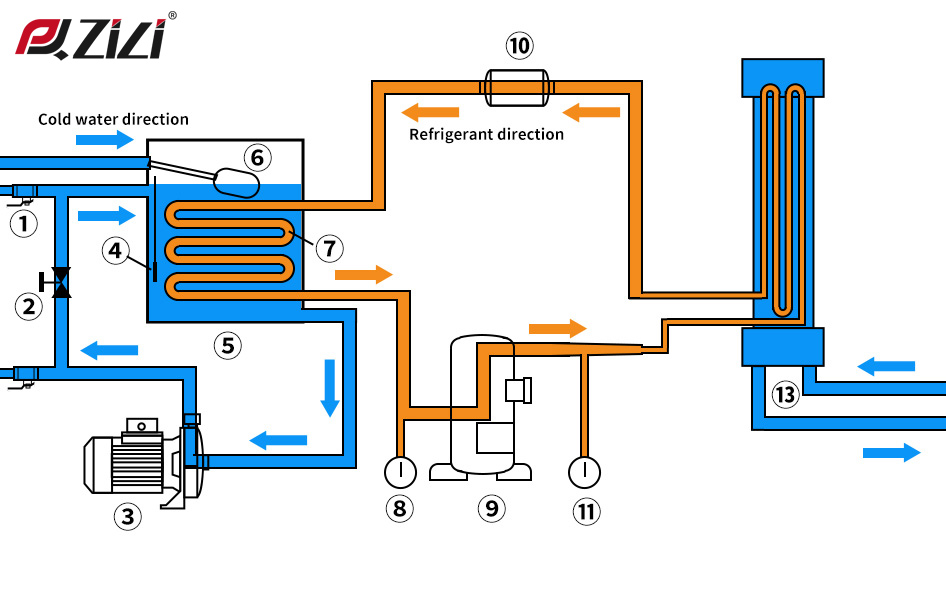

Water-cooled chiller:If it is a water-cooled chiller, the chilled water with heat will circulate back to the cooling tower for a new round of cooling cycle, but one thing to note is that when using a water-cooled chiller, pay attention to the cleaning and maintenance of the cooling tower to avoid Cyclic failure due to dirt.

Efficient:In the early stage of purchase, our company will provide free cooling system solutions, which greatly reduces the time for customers in selecting and distributing machines, and purchasing system chillers will be cheaper and more cost-effective than buying a single machine, which can reduce more budget. In terms of energy consumption, although chillers may be a more expensive initial investment, they can have a more efficient system and save energy consumption, therefore, they can achieve a good return on investment in a relatively quick time.

Strong function: In large buildings, the most important issue is the safety issue, because the refrigerant pipes cannot be installed throughout the building, so the role of the cold water system is very important, compared to using ordinary air conditioners in direct contact with the refrigerant pipes to cool the air, the safety index of the chiller is higher, the cooling effect is more powerful, and the installation is much simpler than this method.

Flexibility: The flexibility of the chiller is a great advantage. It can be installed indoors or outdoors according to customer requirements. It can be equipped with different compressors and refrigerants according to the required cooling capacity and efficiency. In short, chillers are completely customizable options. They can be chosen from many different options and accessories, allowing the chiller to be perfectly adapted to the needs of a specific application.

The above is about the importance of the chiller system in large-scale cooling places. In addition to the production of ordinary chillers, our company can also develop “tailor-made” production and operation solutions, which greatly utilize the flexibility of the chiller to solve customers’ troubles. If you want to know more about the chiller system, you can contact us by leaving a message, and we will serve you as soon as possible~