In the era of industrialization led by science and technology, high-tech industries emerge in an endless stream, and many technical industries need the assistance of chiller to produce with higher efficiency. Different industries have different needs for chiller types, some industries need customized special chiller to meet their needs. Recently we have received a lot of questions from customers. Most of them are questions about shell and tube chiller.

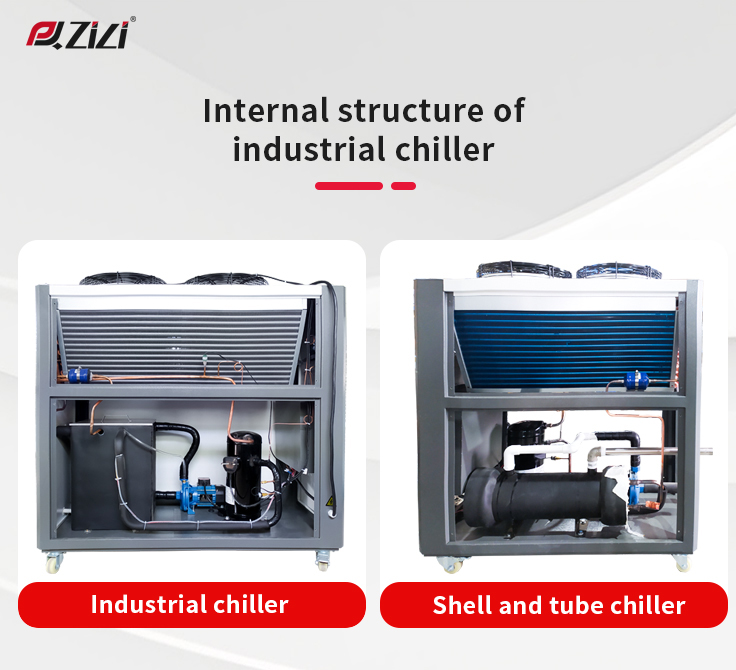

In this article, Pengqiang will answer the main differences between ordinary chiller and shell and tube chiller, among which their biggest difference lies in their structure and application scenarios. The following are some of the main differences:

Pengqiang ordinary chiller: usually includes an evaporator, a condenser, a compressor and an expansion valve. Evaporators and condensers can be plate, tube or other types.

Pengqiang shell and tube chiller: The evaporator and condenser are usually shell and tube type. Shell and tube evaporators and condensers consist of a shell and an internal tube, and the refrigerant flows on the shell side or tube side to exchange heat with the water on the other side.

Pengqiang ordinary chiller: different types of heat exchangers have different efficiency. The heat exchanger of general chiller usually has a higher heat exchange efficiency, but the water quality requirements are higher. For water quality requirements, you can click this link to learn more.

Pengqiang shell and tube chiller: shell and tube heat exchangers are generally resistant to dirt and scaling, and are more convenient to maintain. But the heat exchange efficiency is relatively low, and the electricity consumption will be less.

Pengqiang ordinary chiller: suitable for all kinds of general industrial and commercial cooling needs, such as air conditioning system, food processing, chemical industry, etc.

Pengqiang shell chiller: because the shell chiller is not as high as the ordinary industrial cold water for water quality, it is more suitable for occasions with poor water quality or frequent cleaning, such as cooling tower circulating water system, sewage treatment system, etc.

Compared with ordinary industrial chiller, shell chiller has more unique advantages than industrial chiller in many applications

Shell and tube chiller has strong resistance to dirt and scaling:

The shell and tube heat exchanger of shell and tube chiller has a large channel and flow cross-sectional area, making it not easy to clog and suitable for treating water containing dirt and impurities.

Easy to clean and maintain:

Shell and tube heat exchangers are easier to disassemble and clean than ordinary chiller because of their design and production material. This makes it very convenient in applications that require frequent maintenance.

High temperature and high pressure resistance:

Shell and tube heat exchangers are usually made of high pressure resistant materials that can withstand high temperature and high pressure operating conditions and are suitable for industrial environments that require high durability and high stability.

High reliability:

Because the shell and tube heat exchanger is strong in structure, stable and reliable in operation, it is suitable for continuous working environment so as to reduce downtime and maintenance costs.

Widely applicable:

Shell tube chiller can handle a variety of media, not only limited to water, but also include some chemical solutions and other industrial fluids. Shell tube chiller is essential in a wide range of applications and in some high-risk liquid cooling environment.

Adapt to large flow:

Shell and tube chillers are designed to handle large flow rates, which is saving the budget of purchasing multiple chillers and suitable for industrial processes requiring large-scale cooling, such as power plants, chemical plants and large manufacturing facilities.

In summary, shell and tube chiller has significant advantages and perform very well in many industrial applications, especially in the handling of more fouling fluids, frequent cleaning, and high temperature and pressure environments.