Insufficient water flow is a common reason for industrial water chiller during operation, which can be easily solved.

The insufficient water flow of industrial chiller generally occurs more in winter. The reason may be related to factors such as ambient temperature, the characteristics of the water cooling system and the operating state of the equipment.

The following are some of the reasons that may lead to insufficient water flow in winter chillers:

Cooling water temperature is too low: In the cold winter months, the temperature of the water may decrease, resulting in a decrease in the fluidity of the cooling water. This can slow down the water flow and affect the cooling effect.

Cooling water freezing: In extreme cold conditions, the cooling water may freeze, causing water flow to be impeded. Ensure that the cooling water used is properly freeze-proofed or take other anti-freeze measures.

Frozen Water Pipes: The chiller's water lines may be affected by freezing during extremely cold winter months, restricting the flow of water. The use of insulation or other anti-freeze measures can help prevent freezing of water lines.

Valve Problems: Valves in the chiller may be affected by cold weather during the winter months, causing them to close or open poorly. Please make sure the valves are not frozen and are functioning properly.

Water Pump Problems: The water pump in the chiller may be affected by cold temperatures, resulting in inadequate water flow. Check the pump for proper operation and make sure its blades are not frozen or otherwise affected.

Improper Cooling System Design: Some cooling systems may not be designed for cold winter conditions, resulting in inadequate water flow in cold temperatures. Winter conditions should be considered and measures taken during design and installation. Pengqiang Instruments' chillers are perfectly designed to completely avoid failures due to improper design.

If the chiller has the problem of insufficient water flow in winter, it is recommended to check the above possible causes first and take corresponding measures according to the specific conditions, or contact our staff. We will provide perfect after-sales solutions.

So how to solve the cause of insufficient water flow of the chiller if encountered?

Check the water source: Ensure that the water supply pipeline is smooth and the water source is sufficient. Check whether the water valve is open to ensure that there is enough water flow into the chiller.

Check the pump: If the chiller uses a water pump, check whether the pump is running normally. It may be necessary to check the power and cable connections to the pump.

Check the water filter: If there is a water filter in the system, check to see if the filter is clogged. If the filter is dirty, it can be cleaned or replaced.

Check the water lines: Check the water lines of the chiller for leaks or blockages. Sometimes sediment may build up in the water pipes, causing the water to flow poorly.

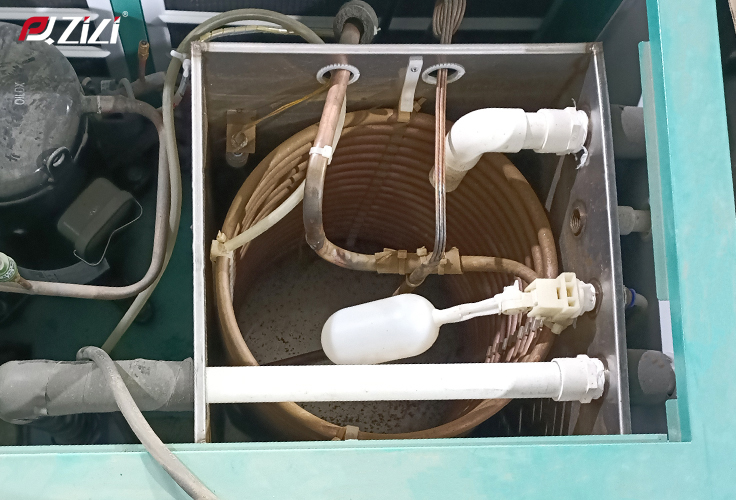

Check the water tank: If the chiller has a water tank, check whether the water tank level is normal. A low water level in the tank may result in insufficient water flow.

Check the pump inlet and outlet valves: If there are inlet and outlet valves, make sure they are open. Closed valves may restrict water flow.

Check pump runtime: Some systems may have set a limit on pump runtime. Check to see if the runtime limit has been reached and the pump needs to be restarted.

Check for system alarms: Check to see if the chiller is displaying any fault or alarm messages. Take appropriate action based on the information displayed.