After serving a number of enterprises, our company, Pengqiang Group, found that many customers do not know whether to choose ordinary scroll chiller or choose screw chiller in the operation of large-scale refrigeration and large space, pool refrigeration. Then this article can help answering this question.

There are some differences between screw chiller and ordinary industrial chiller in refrigeration principle, structural design and performance.

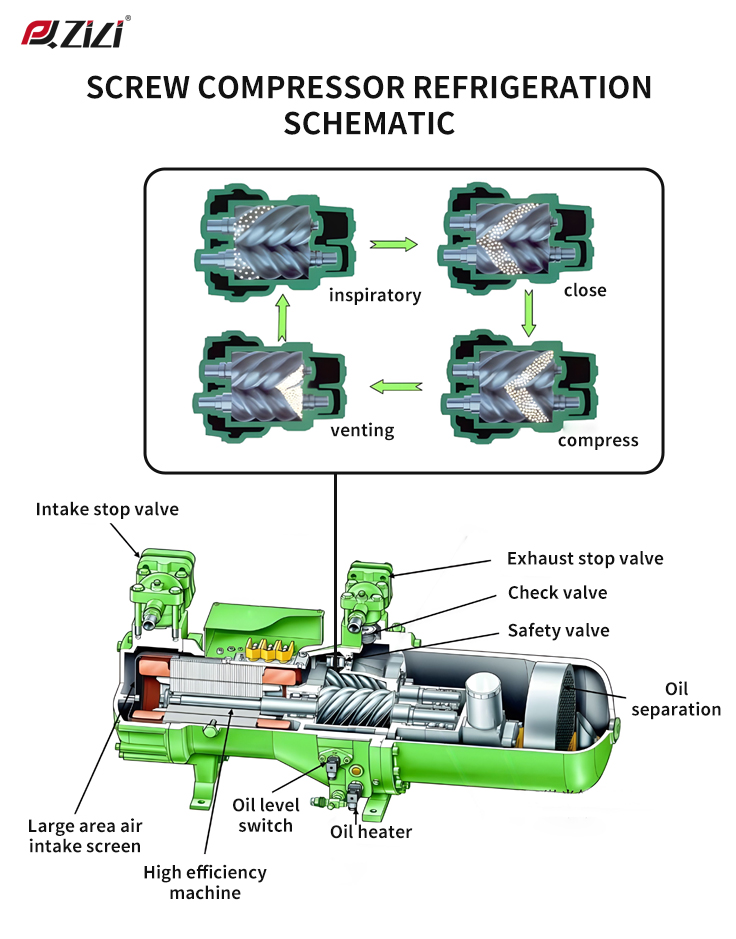

Refrigeration principle:

Screw chiller: It use screw compressor as the main refrigeration compressor. Screw compressor realizes gas compression through the rotation of two screws, which is an efficient and energy-saving refrigeration technology.

Ordinary industrial chillers: Other types of compressors may be used, such as reciprocating compressors, centrifugal compressors, scroll compressors, etc. Different compressor types will affect the refrigeration efficiency and energy efficiency.

Structure design:

Screw chiller: It has a relatively simple structure, usually composed of screw compressor, condenser, evaporator and control system. Screw compressors are compact and occupy relatively little space.

Ordinary industrial chillers: It has different structural designs depending on the type of compressor used. Generally includes compressor, condenser, evaporator, expansion valve and other components.

Operating efficiency:

Screw chillers: Usually with high energy efficiency, screw compressors are designed to be more efficient at partial load operation. It is also suitable for industrial applications with long and stable operation.

Ordinary industrial chiller: In some cases, it may be slightly less efficient at partial load than the screw chiller.

Scope and scale of application:

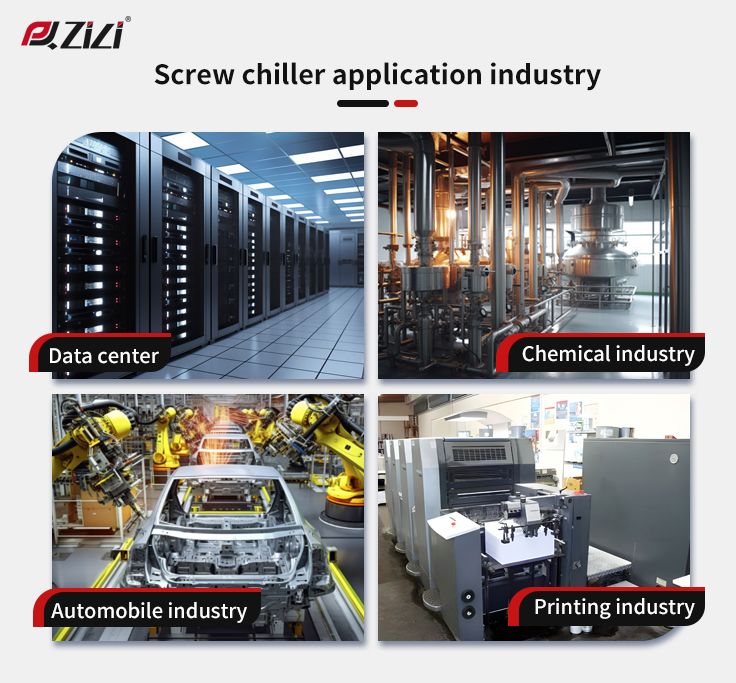

Screw chillers: Suitable for large industrial and commercial systems, especially those requiring long, efficient operation. It is common in large manufacturing, energy production and data centers.

Ordinary industrial chiller: This can be suitable for small and medium-sized industrial and commercial applications, according to specific needs to choose different types of refrigeration units.

Control system:

Screw chillers are usually equipped with advanced electronic control systems that allow for precise temperature control and automated operation.

Ordinary industrial chiller: The complexity of the control system may be low, depending on the model and manufacturer.

Overall, the choice of screw chiller or ordinary industrial chiller should be weighed according to the specific application needs, energy efficiency requirements and budget and other factors. In some large industrial applications with high energy efficiency requirements and long-term stable operation, screw chillers may be more suitable.

The choice of ordinary industrial chiller and screw chiller needs to consider a number of factors, including application requirements, cooling capacity, energy efficiency requirements and budget.

Choose ordinary industrial chiller:

Application requirements: Ordinary industrial chiller is suitable for small and medium-sized industrial and commercial applications. If your application does not require extremely high cooling capacity, a general industrial chiller may be an affordable option.

Budget considerations: Ordinary industrial chillers are usually highly cost-effective and suitable for situations with limited budgets. In projects with more sensitive budgets, you can consider choosing ordinary industrial chiller.

Small and medium-sized applications: If your industrial refrigeration needs are small and medium-sized, such as small manufacturing, commercial air conditioning, etc., ordinary industrial chiller may be able to meet the requirements.

Energy efficiency requirements are not a top priority: Ordinary industrial chillers may not be as efficient as screw chillers in terms of energy efficiency, so if energy efficiency is not a top priority for your application, consider regular industrial chillers.

Choose screw chiller:

Large-scale applications: Screw chillers are suitable for large-scale industrial and commercial applications, especially where high cooling capacity and energy efficiency are required.

High energy efficiency requirements: If your project has high energy efficiency requirements, screw chiller may be a better choice. Screw compressors typically offer higher energy efficiency under partial load.

Long-term stable operation: The screw chiller has stable performance during long-term operation, which is suitable for industrial production or data center scenarios that require continuous cooling.

Advanced control system requirements: Screw chillers are often equipped with advanced control systems that allow for more precise temperature control and smarter operation.

Environmental protection requirements: If your project has high environmental protection requirements, screw chiller usually uses some more environmentally friendly refrigerant, in line with the requirements of sustainable development.

Cooling Requirements: Determine the cooling requirements of your project, including the required cooling capacity, stability requirements, and precision of temperature control.

Energy efficiency standards: According to energy efficiency standards and requirements, we need to select refrigeration equipment that meets the needs of the project.

Budget constraints: Ensure that the equipment selected is within the project budget while considering performance requirements.

Future development: Considering the future development scale and demand of the project, we can select equipment with certain expansion potential.

In general, the choice of ordinary industrial chiller or screw chiller depends on the specific project needs and constraints. When making decisions, it is best to consult our staff, Pengqiang will provide free solutions to satisfy customers, to ensure that the selected chiller can best meet the requirements of the project.