The main function of industrial chillers produced by Pengqiang Group is to provide cooled water for equipment/products to achieve the purpose of cooling. Industrial chillers are already an integral part of plastics, electronics, chemicals, food preservation, ink printing, pharmaceuticals, machinery and other industries.

The cooling effect of the chiller depends on its quality. However, in the use of the chiller, there will always be unavoidable losses. Therefore, we need to regularly record and analyze its operating parameters, check the use of refrigerant, frozen oil, etc., and regularly do maintenance operations for it.

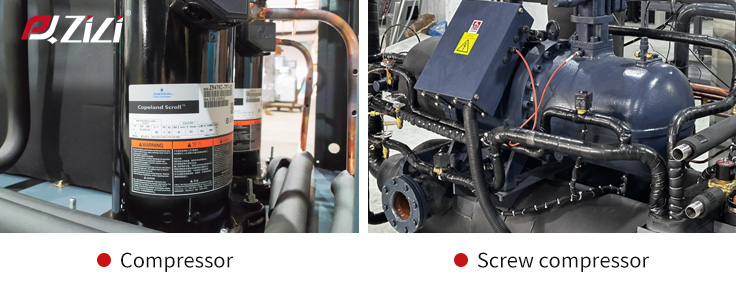

1. Check the compressor of industrial water chiller regularly

Compressor is the “heart” of all the chiller, and plays a fundamental role in refrigeration.So the compressor is good or bad directly affects the stability of the chiller when used.

If the compressor needs to repair, the cost is relatively high, especially the screw compressor because it is more precision and more expensive. Therefore, if you hear the compressor has abnormal sound or other conditions, please be sure to find a professional engineer for inspection, and find out the problem and then fix it to avoid greater issues.

2. Clean the condenser and evaporator of the screw chiller regularly

The condenser/evaporator is the second important component of all industrial chillers, it is best to clean regularly. If there is too dust in the area, it is necessary to shorten the cleaning period.

Of all the chillers, only the water-cooled condenser has an open circulation loop for the cooling water, so compared to air-cooled, water-cooled chillers are more prone to decomposition and deposition of impurities to form scale on the water pipes, which affects the heat transfer.

Excessive scaling will also reduce the cross-section of the cooling water circulation, reduce the amount of water and increase the condensing pressure. So, if the quality of the tap water is poor, it is necessary to check and clean frequently to remove the scale in the pipe, and it is best to carry out water treatment operations on the tap water.

Among them, the quality of the accessories used by the manufacturer is also very important, the production of industrial water chillers in Pengqiang group are generally made of copper tube evaporator + aluminum fin combination. It is more robust and can prevent damage to the chiller due to other external causes.

3. Test the safety valve of the chiller regularly

The condenser and evaporator are pressure vessels. According to the regulations, the high pressure end of the screw-type chiller that is the condenser body should be installed a safety valve. Once the machine is in a non-normal working environment, the safety valve can be automatically relieved in order to prevent high pressure to hurt the human body.

4. Replace the lubricating oil of the screw industrial chiller regularly

After long-term using, the oil quality of the lubricating oil will deteriorate. The impurities and water inside the oil will increase, so it is also necessary to regularly observe and check the oil quality. If any of the issues have been found, it should be replaced in a timely manner to prevent the bigger losses.

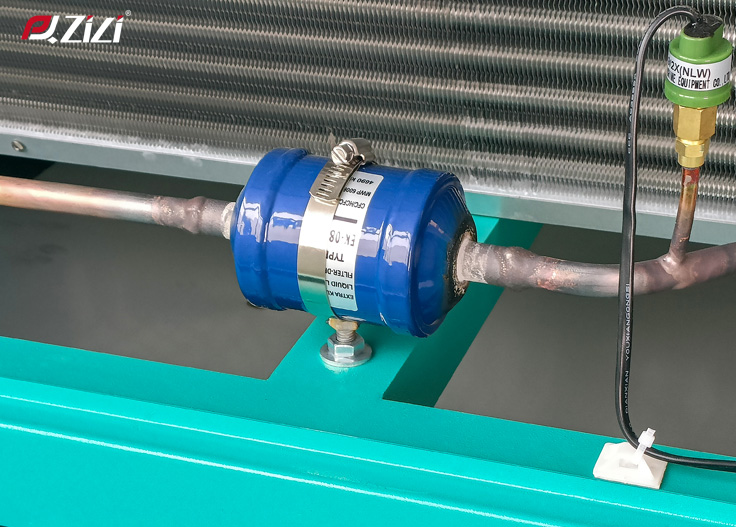

5. Replace the filter drier of the industrial chiller regularly

Due to the immiscible nature of water and refrigerant, the existence of the filter drier is particularly important to ensure that the refrigerant carries out normal circulation. If the filter drier is out of control, it will result in the system contains water. This will greatly affect the operating efficiency of the chiller and reduce the production. So it is very important to make the inside of the chiller system to keep drying. And it needs a regular check and replacement.

The above is a few suggestions of how to maintain the chiller. It can help to increase the life service of the chiller and reduce the production costs.