During the operation of the chiller, it is inevitable that some problems will occur, especially in winter. The frost of the expansion valve is one of the problems that may occur during the operation of the machine. What is the reason for the frost of the expansion valve of the water chiller?

Too low ambient temperature: If the ambient temperature is too low, the surface of the chiller may cool below the dew point temperature, causing the moisture in the air to condense into frost.

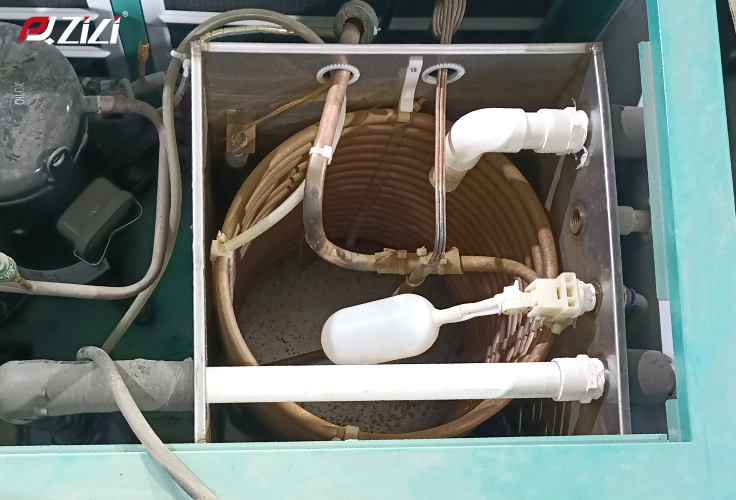

Evaporator over-cooling: The evaporator is a part of the chiller used to absorb heat and evaporate the refrigerant. If the evaporator temperature is too low, the surrounding moisture may condense into frost when it comes into contact with the chiller, especially for the air chiller.

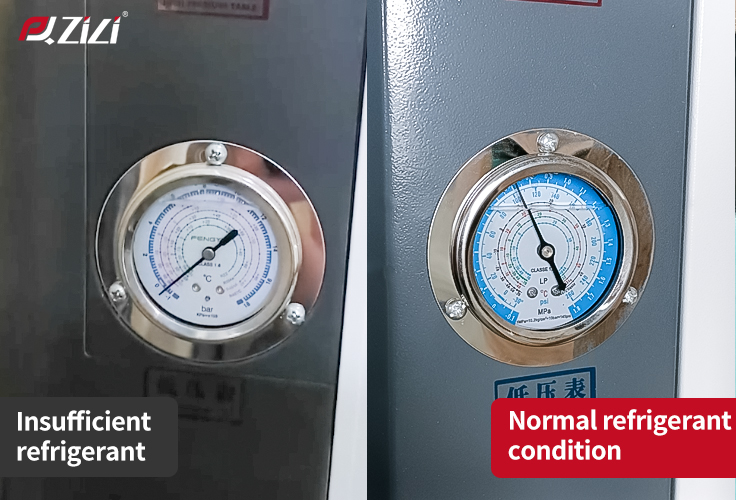

Excess or insufficient refrigerant: The amount of refrigerant in the chiller is required to be precise. Excess or insufficient may lead to system performance problems, one of which is frost in the expansion valve.

Expansion valve failure: the failure of the expansion valve may lead to abnormal refrigerant flow, which may affect the normal operation of the system and resulting in frost problems. If you encounter such problems, please contact our company immediately, we will actively help you solve the problem.

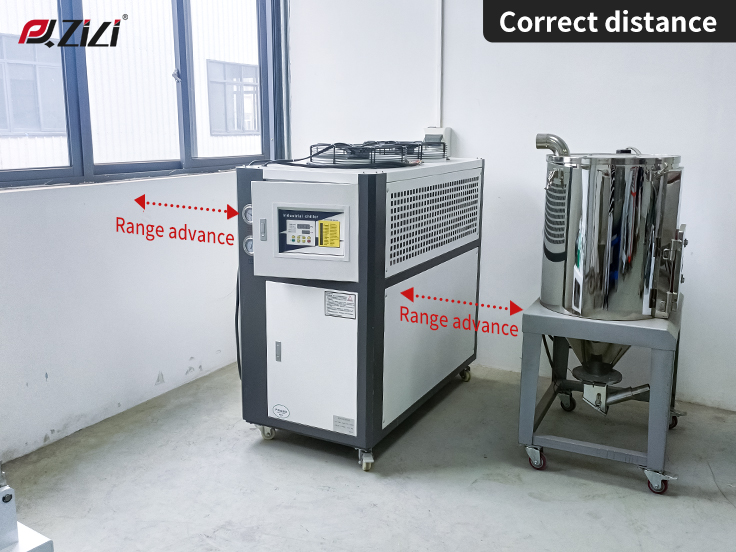

Poor air flow: If there are obstacles around the chiller that preventing the normal flow of air, it may cause the surface temperature to drop and resulting in frost.

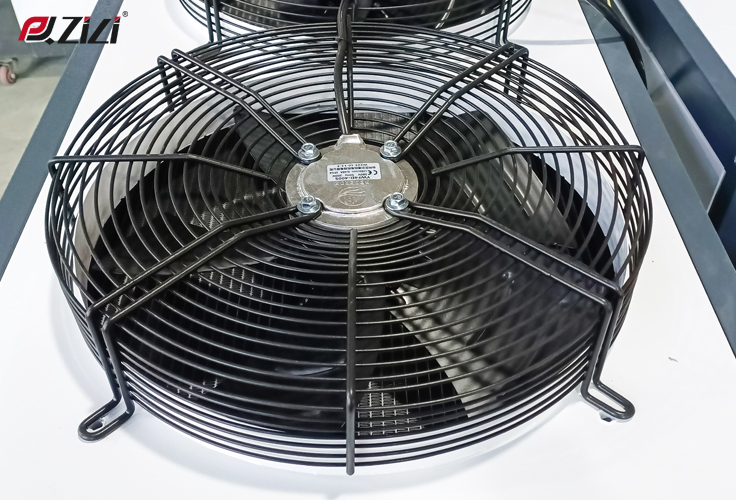

Improper cleaning of the evaporator and fan: If the surface of the evaporator is covered with dust or dirt, the thermal conductivity may be reduced that affecting the operation of the system and possibly causing frost problems.

Due to the sudden drop in temperature in winter and some environmental impacts, the frost of the expansion valve will become a common problem, which requires buyers to check and maintain more carefully in the autumn and winter. The industrial chiller produced by our company is also equipped with six protection alarm systems. If these problems occur, it will alarm to remind the user.

The frosting of the chiller expansion valve can lead to a series of problems, some of which may affect system performance and operational efficiency.

Reduced system efficiency: Frost can cause the surface temperature of the chiller dropping, which will cause the cooling efficiency of the system to decrease. Expansion valve frosting can affect the flow of refrigerant through the system, which will affect the entire cooling process.

Increased energy consumption: Frost increases the workload of the chiller because the system requires more energy to maintain the set cooling effect. This can lead to an unnecessary increase in energy consumption.

Expansion valve failure: Long-term frosting problems can lead to expansion valve failure, which affects the normal operation of the entire refrigeration system. This may require more expensive and complex repairs.

System freezing risk: If the frost problem is not resolved, it may lead to frost in other parts of the system, and may even cause some components of the chiller to freeze, leading to more serious failures.

Shortened equipment life: Frost formation can cause temperature fluctuations in the system, which can accelerate wear and aging of the equipment, thereby reducing the service life of the equipment.

Solving the frost problem of the expansion valve is crucial to maintain the normal operation of the system, improve the operating efficiency of the chiller, reduce the production energy consumption. And maintaining the machine well can also extend the service life of the chiller equipment.

Check the refrigerant of the water chiller: ensure that the amount of refrigerant is within the range specified by the manufacturer.

Check the status of the expansion valve of the chiller: ensure that the expansion valve is not faulty, which may require professional and technical personnel to use appropriate tools and equipment to check the performance and flow of the expansion valve. Contacting us in time if needed, our engineers will give you a detailed inspection plan.

Clean the evaporator and fan: make sure the surface of the evaporator is clean and free of dust or dirt. This can be done by regularly cleaning the chiller evaporator and fan to ensure the effectiveness of the heat exchange.

4. Ambient temperature control: if possible, consider installing insulation materials or increasing the ambient temperature to prevent the surface temperature of the chiller from falling below the dew point or transfer the chiller to a more balanced indoor temperature position.

5. Check the system pressure: ensure that the chiller system pressure is within the normal range. Abnormal system pressure can affect refrigerant flow and evaporator performance.

6. Regular maintenance: the method of chiller maintenance has been mentioned before, you can click on the previous article connection to review. Regular maintenance of the chiller is including cleaning, checking and calibration of various components. This helps ensure the stability and efficiency of the chiller system.