There are many different functions and types of chiller produced by our company, but most of them are sealed cycle.

The sealed cycle refers to that the chiller outputs cold water through the sealed pipe to cool the corresponding machine, and after cooling, the water flows through the sealed pipe again to cool down and complete the cycle action.

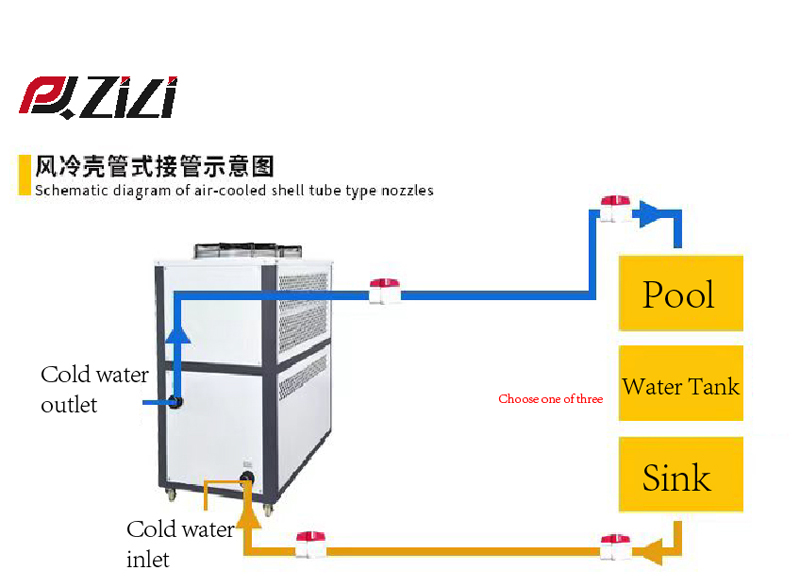

However, for customers who need to cool the pool or water tank, the sealed cycle chiller is not the best choice, so our company can also customize the open water chiller according to customer needs.

Sealed cycle chillers are usually equipped with plastic or stainless steel tanks inside the chiller, and the cooled water is sent to the tank through the main supply source, where it is distributed to the various climate control Spaces through the pump. As the second law of thermodynamics states, heat always changes from hot to cold, so the chilled water absorbs ambient heat from the air-conditioned space in the air processor. Fans then force cooling air into the space through a system of ducts. The warm water is then returned to the chiller to cool again.

At the same time, the heat absorbed by the refrigerant in the evaporator needs to be transferred to make the refrigerant absorb more heat. The low pressure, high temperature refrigerant moves from the evaporator to the electric compressor, thereby increasing the pressure and temperature.

After that, the refrigerant enters the condenser. Water-cooled chillers use water to surround refrigerant pipes and draw in heat. Water is then pumped into the cooling tower to release the heat. After condensation, the refrigerant lowers its pressure (and temperature) through an expansion valve and returns to the evaporator to begin the process again.

In general, sealed cycle chiller used in most industries, especially mold cooling and machinery industries, need the help of chiller.

Water-cooled open chiller is an open structure, generally speaking, open chiller is a scroll compressor, this chiller has a simple structure, low cost, and convenient maintenance in the later period, so it is very popular with users.

There is only a perfect refrigeration and control system inside the open chiller, and its waterway system is not perfect. Because its unit does not have a water tank pump, customers need to match according to their actual situation.

Because the open chiller does not have a water tank pump, it is convenient for customers to choose the volume of the water tank, the water pump, etc., according to the actual needs, and the closed box chiller will not be limited by space, so that it can be better matched according to the different equipment requirements and process requirements of customers.

In general, customers who need to cool down a small water tank for an ice bath can customize a smaller power chiller, if it is to cool the pool of a hotel or a large site, you can use a higher number of chiller to achieve cooling purposes.

Pengqiang Zili professional chiller, according to customer needs, free to provide a lot of chiller solutions, the above is the difference and use of sealed cycle and open waterway, if you are interested in this article or have better suggestions, you can leave a message below or send us an email interaction ~