In Winter, the usage rate of cooling-water machine will be greatly reduced compared to the rate in Summer. If the machine is not used very often, it will freeze in cold weather, which may lead to some problems in the next year. So we should carefully maintain the machine, especially in Winter, so that we can use it better in next year.

So how should we maintain industrial chiller in Winter?

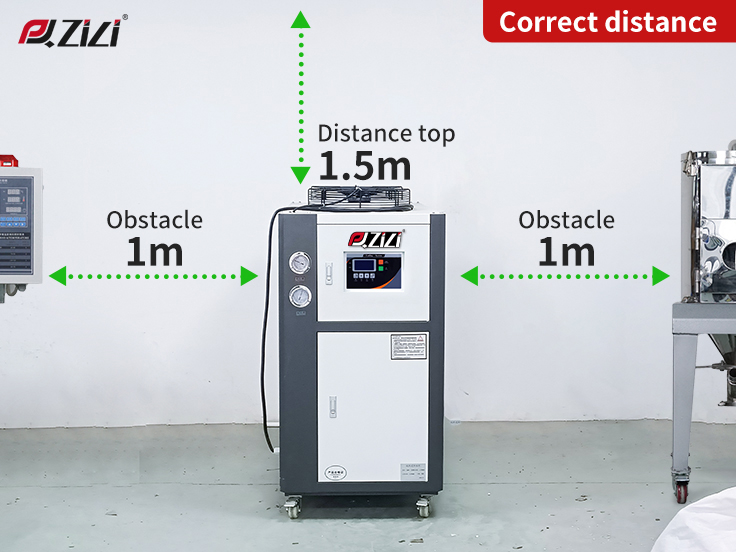

Water chiller placement: The air outlet (air cooler) of the chiller is at least 1.5m away from the obstacle, and the air inlet (filter) is at least 1m away from the obstacle. This will help to prevent dust accumulation, otherwise, it is resulting in poor heat dissipation during use and high temperature alarm.

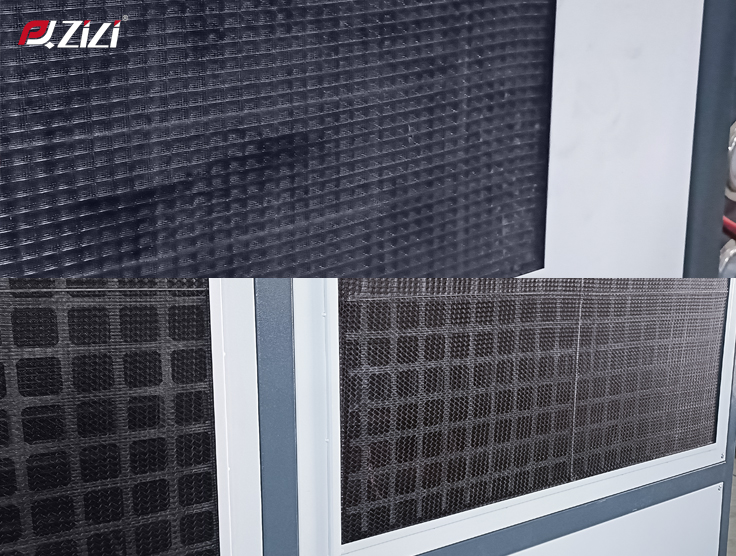

Cleaning & Dust removal: Regularly clean the dust and impurities on the surface of the condenser with the compressed air gun or rag to avoid the poor heat transfer of the compressor during use, which leads to the temperature of the mold not falling and the delay of product production.

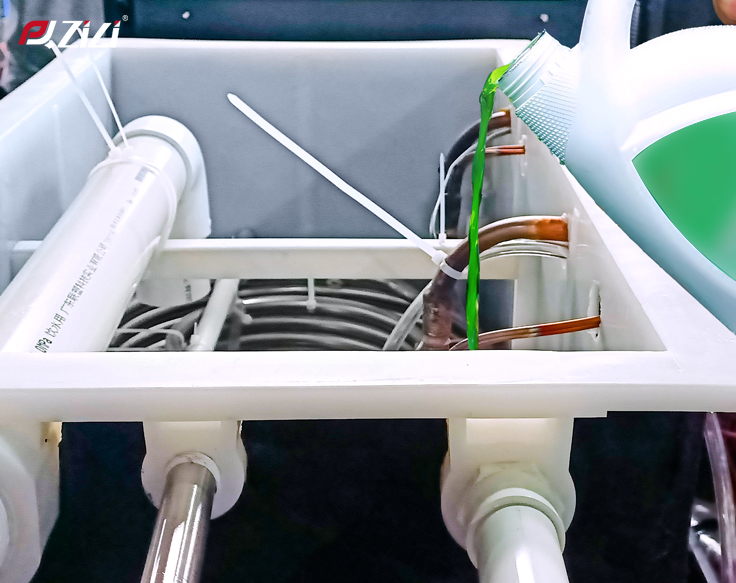

In the cold winter, in order to prevent the stored water inside the industrial chiller from freezing and freezing other parts, we can add antifreeze to prevent the cooling fluid freezes. If you choose the wrong antifreeze or use it improperly, it will cause the damage to the chiller machine especially for the sealing of the internal pipeline.

Therefore, in Winter, we should pay attention to the following five points when choosing antifreeze: (1) stable chemical properties; (2) Good frost resistance; (3) appropriate low temperature viscosity; (4) corrosion and rust prevention; (5) The rubber sealing catheter has no expansion and no corrosion.

Low concentration antifreeze is preferred

When the antifreeze meets your needs, the lower the concentration, the better.

The shorter the use time, the better

Antifreeze used for a long time will have a certain deterioration, more corrosive, and its viscosity will change with time. Therefore, it is recommended to replace the antifreeze once a year to prevent the antifreeze from corroding the chiller pipeline and causing losses in production.

Different brand of antifreeze should not be mixed.

Although the ingredients of antifreeze for different brands are the same, the additive formulations are different. In order to prevent accidents, we still recommend you use the antifreeze in same brand. We need to avoid chemical reactions, precipitation or bubbles in the chiller, otherwise it may increase the maintenance costs.

Replace the circulating water regularly

The cooling water in the chiller will form scale during the circulation process, which will affect the normal operation of the chiller system.If we want the chiller working properly, it is recommended to replace the circulating water every 3 months. And it is best to choose pure water or distilled water to reduce the formation of scale and keep the waterway unimpeded.

Because of the low use frequency in Winter, we need to pay more attention to the state of cooling water to prevent a large number of scale and corrosion impurities.

Drain the water from the chiller

If the chiller is not used at all in winter, it is necessary to drain all the water in the chiller system to prevent the residual water from freezing.

If the water is not drained clean, the water will freeze and expand at low temperatures, which will cause the pipes and other components of the chiller to be damaged.

So when packing the machine, we should thoroughly clean the scale. The pipeline should be purged with high pressure air rifle to check whether there is any water residue to avoid the corrosion and the freezing of the equipment. After the inspection, the cold water machine can be collected into the warehouse for the use of next year.

Store the chiller properly

After cleaning and drying the inside and outside of industrial chiller, the panel was reinstalled. It is recommended to store the chiller temporarily in a place that does not affect production and cover the machine with a clean plastic bag to prevent dust and moisture from entering the equipment.